Infrastructure

State-of-the-art infrastructure, designed to preserve the essence of nature while elevating quality and hygeine.

At Capricorn, our world class infrastructure forms the backbone of our food processing operations.

Ensuring excellence at every step of the journey, our advanced facilities encompass cutting-edge processing units, modern machinery, and cold chain network, all meticulously designed to bring the best of nature’s bounty to your plate.

- Reliability

We take great pride in our consistent delivery of high-quality products

- On Time Delivery

We always honor our time commitments

- Corporate certifications

We hold all the essential certifications

Environmental Control Ripening Chamber (ECRC)

Capricorn has an automated ECRC chamber with automatic gas injection and is temperature and humidity controlled to replicate the ripening process as close to as nature

Expert-led quality control and cutting-edge labs

With years of experience and a keen eye for detail, our dedicated quality control experts meticulously oversee every aspect of our process, ensuring that only the best quality product meet our rigorous standards.

We constantly monitor the quality of our in process material in our value chain

Standardization tank

Evaporator

Sterilisation of pulp & concentrate process

The Company has state of the art sterilisation unit with total capacity of 40 MT an hour. The steralisation units are of the make Ing. A. ROSSI. and CFT.

Packaging

At Capricorn, we pay special attention to packaging. It is an intrinsic part of the TQM. Different kinds of tropical fruits are processed using fully operational-and sophisticated machinery equipment from CFT and Ing. A. ROSSI. Packing materials are sourced from certified vendors and packaging is done in aseptic bags ranging from 20 litre to 1,000 litre packs and OTS cans. We follow ISO 9001−2008 & FSSC 22000 standards for ensuring the quality of our processed products.

Cold chain infrastructure

With a keen focus on quality and sustainability, our cold chain infrastructure guarantees the preservation of freshness and nutritional value. Our temperature-controlled storage and refrigerated transportation ensure that every product retains its natural goodness and flavor, delivering a premium experience to our customers.

Sustainability

Committed to environmental responsibility, our plants reflect our dedication to minimizing our ecological footprint. By employing energy-efficient technologies like solar-powered systems and efficient waste management, we uphold our commitment to sustainability while maintaining operational efficiency

Certifications

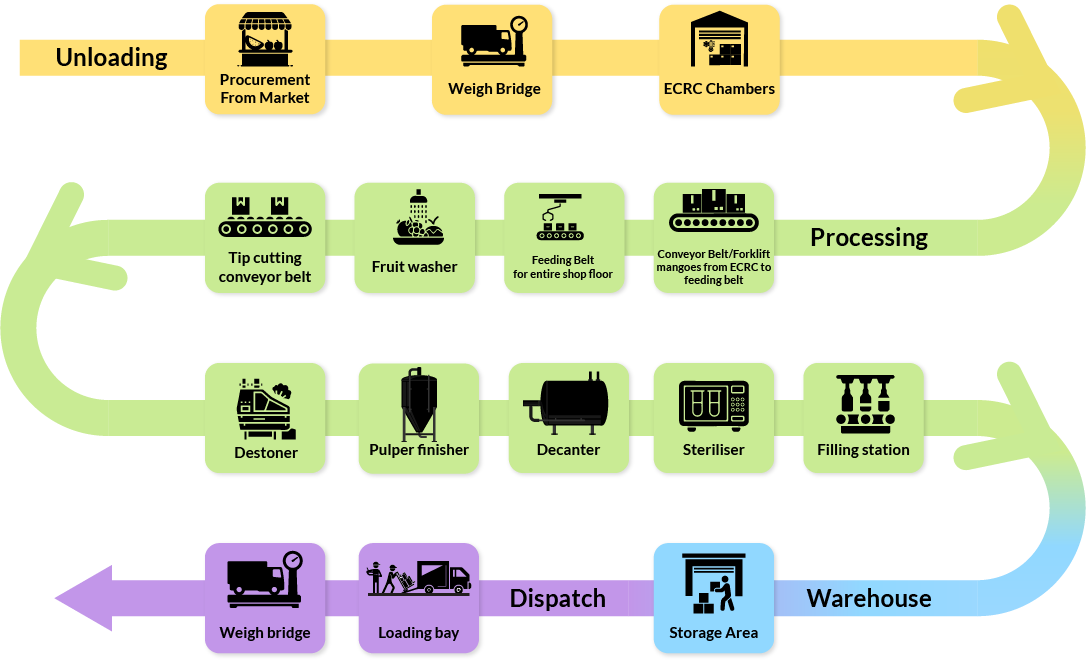

Sourcing to Dispatch process